A reciprocating air compressor is an assembly of various parts. When these parts deliver their duties in a pre-determined order, we get compressed air.

The uses of compressed air are unlimited in the engineering sector. You can use compressed air very effectively in the below-mentioned industries.

Read: 8 Places Where You Can Use Air Compressor Effectively

If you are familiar with the parts of the reciprocating air compressor, you can rectify simple faults on your own.

Every single part is important for the efficient working of an air compressor. So, here I will like to share the details about major compressor parts.

If you read this article carefully, it will benefit you as like Industrial air compressor service engineer.

These compressor spare parts are used in the reciprocating air compressor manufactured by Chicago Pneumatics, Ingersoll Rand, Atlas Copco, etc.

So, here is the list of Important Parts of Reciprocating Air Compressor

Frame/Crankcase

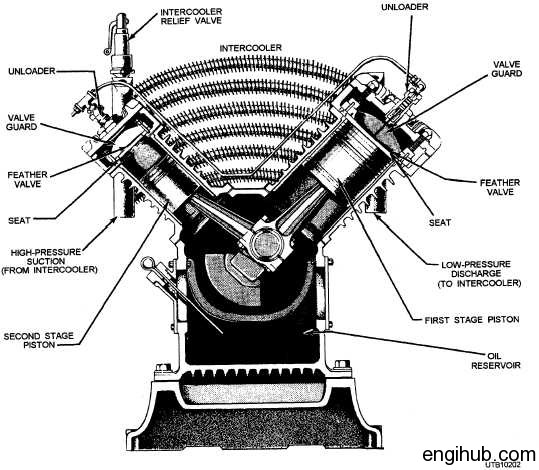

A crankcase which is also known as a Frame is a heavy, rugged housing containing all the rotating parts. A cylinder and crosshead guide is also mounted on the crankcase.

Bearing housing is fitted on a crankcase with accurately bored to fit main bearings. So, misalignment or eccentricity is avoided.

This is a totally enclosed rigid cast iron body in square or rectangle shape, often working as an oil sump.

High-grade S.G. Iron crankshaft in one piece in design, dynamically balanced with counterweights, avoid any twisting.

Crank pin & journals duly ground & polished ensure the long life of bearings. A flywheel is fitted on the crankshaft.

Cylinders

Graded cast iron cylinders designed with a water jacket in a water-cooled air compressor to remove heat generated during compression.

Designed for streamlined air passage & maximum numbers of valves, the cylinder provides a smooth flow of air, thereby minimizing the pressure drop.

Pistons

Special Aluminum alloy pistons for non-lubricated air compressors and graded cast iron pistons are used for lubricated models. Piston Rings are used for sealing a cylinder.

Connecting Rod

Forged alloy steel connecting rod is duly normalized, and are designed to provide minimum thrust on cross head bearing surface.

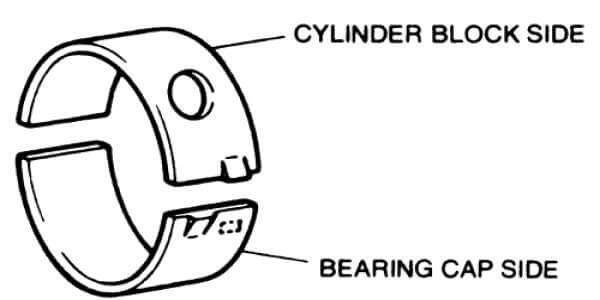

Main Bearings & Big End Bearings

Copper lead alloy is designed for long life. It gives perfect rigidity to running gear.

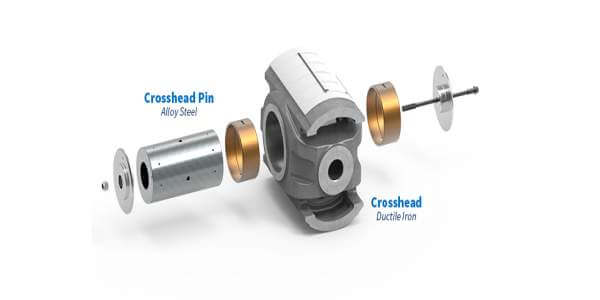

Cross Slide & Cross Head

Manufactured from high-grade S.G. Iron material. Its low inertia along with a low friction cross slide ensures the perfect running of the crosshead.

Stainless Steel plate type or spring type valves are arranged symmetrically in suction & discharge provides longer life.

Oil Pump

It feeds oil to main bearings, connecting rod bearings & cross slides. The oil pump regulates the oil pressure by pressure regulating the screw.

Along with the above parts, some other small parts like oil seal ring, small end bushing, Suction filter element, crosshead pin, heads, belts nut, bolt, gaskets, etc. are used.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.